GEOMER - System for Geometric Parameter Measurement of Pipes

Systems for Geometric Parameter Measurement of Pipes

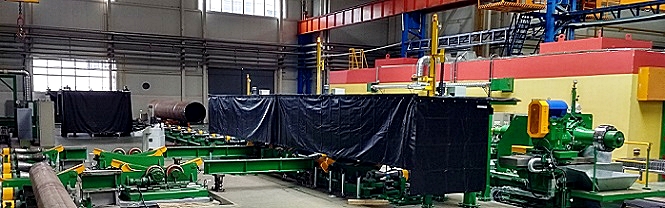

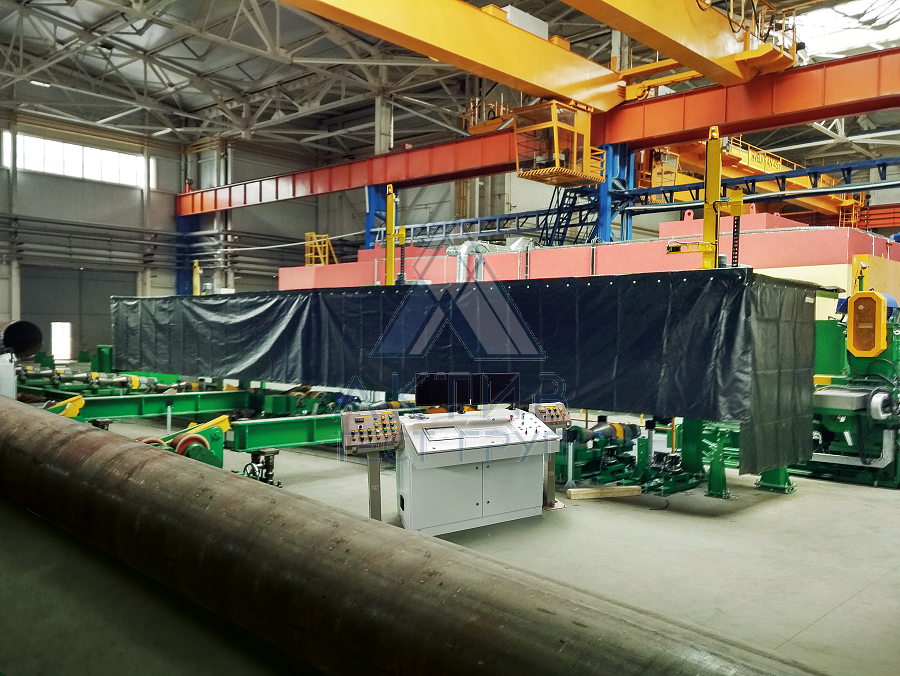

Automated systems of GEOMER series manufactured by ActiveTestGroup (Russia) for geometric parameter measurement of longitudinal electric welded trunk line pipes Ø426-1420 mm at production. The objects are located on roller conveyor with lifting and reversible rollers. System uses contact-free, laser, triangulation measurement method and measures the following parameters:

Automated systems of GEOMER series manufactured by ActiveTestGroup (Russia) for geometric parameter measurement of longitudinal electric welded trunk line pipes Ø426-1420 mm at production. The objects are located on roller conveyor with lifting and reversible rollers. System uses contact-free, laser, triangulation measurement method and measures the following parameters:

bevel angle and bevel dulling, pipe wall thickness, diameter, roundness, cutting angle and total pipe warning. After pipe is fully rotated, the following parameters of welds: weld gain height, weld edge width, weld edge shift, profile deviation to the left and to the right.

Configuration:

Configuration:

- manipulator of laser gage positioning on the first end of pipe with controller;

- manipulator of laser gage positioning on the second end of pipe with controller;

- manipulator of laser gage positioning on the pipe body with controller;

- mountings of laser gage fixture and positioning for measuring pipe warping;

- mountings of laser gage fixture and positioning for measuring pipe weld parameters;

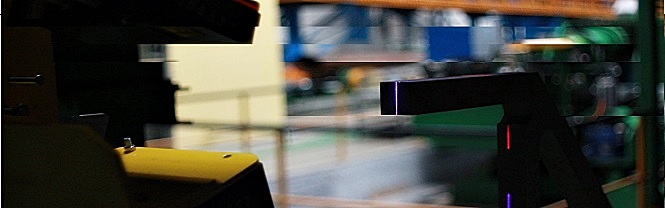

- a set of laser gages with protecting screens;

- a set of incremental encoders;

- laser gage for preliminary definition of pipe diameter;

- videocamera for tracking the weld;

- control panel with switch, computer, touch panel;

- reference blocks;

- darkening booth.

More.