Systems for measuring geometric parameters of blades

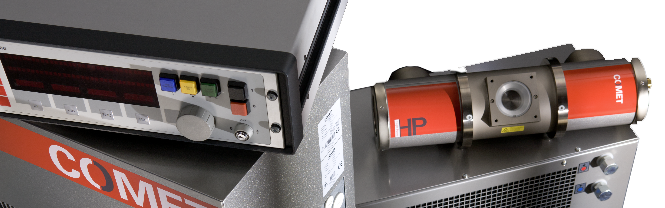

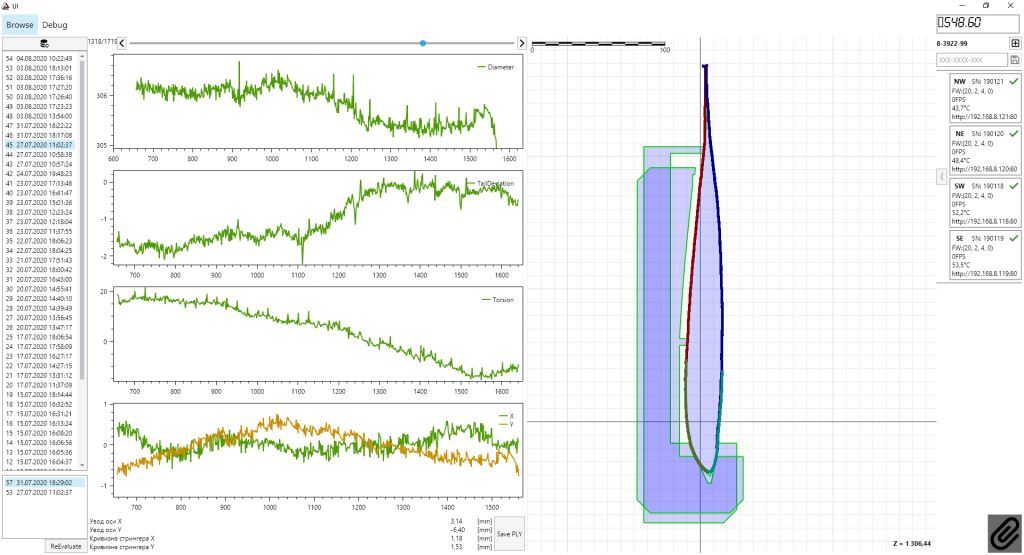

The automated system «Geometra» for measuring geometric parameters of the blade is intended for non-destructive inspection of such geometric parameters of the blade as:

- Chord width of the blade;

- Blade twist;

- Blade axis run-off at the end of the blade;

- Afterbody deviation from the nominal position;

- Tail stringer curvature.

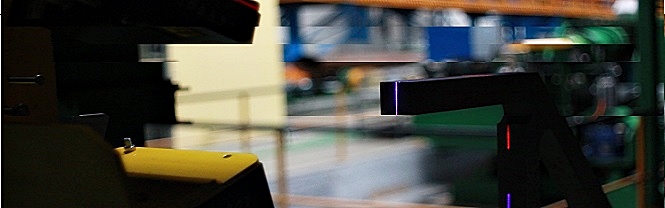

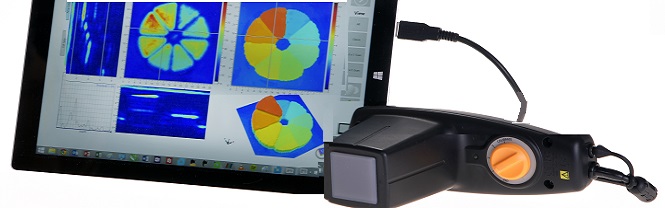

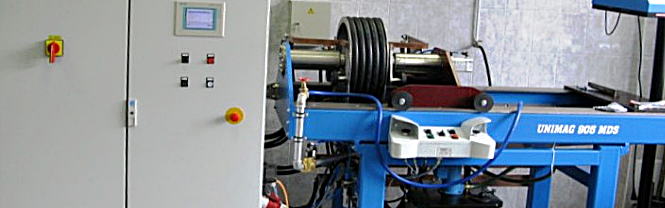

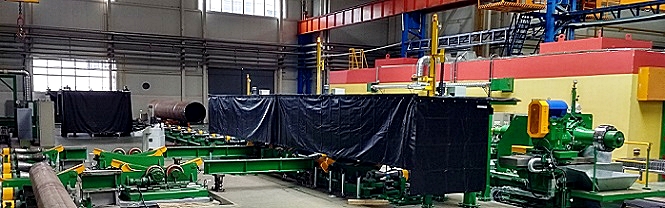

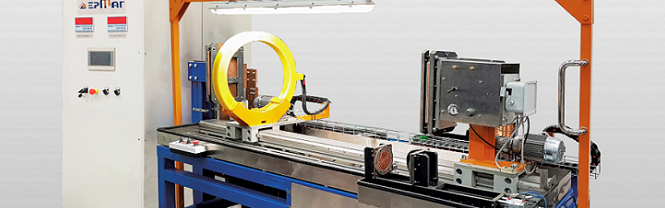

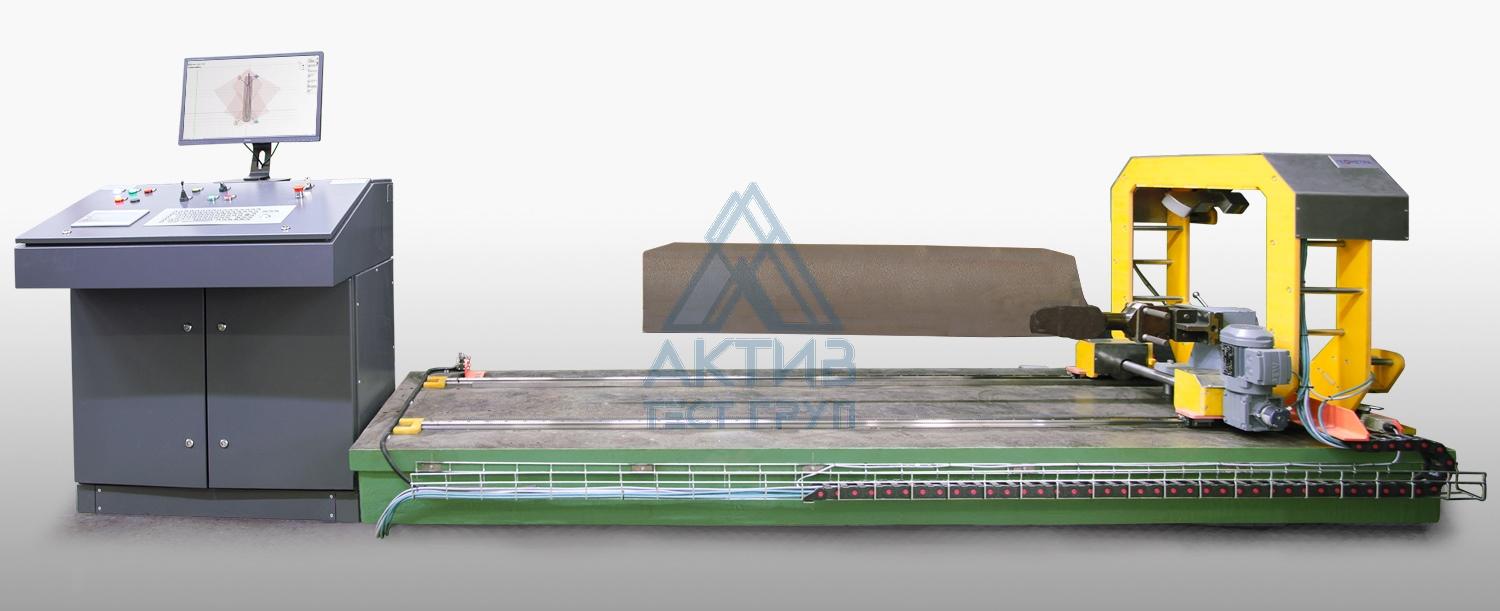

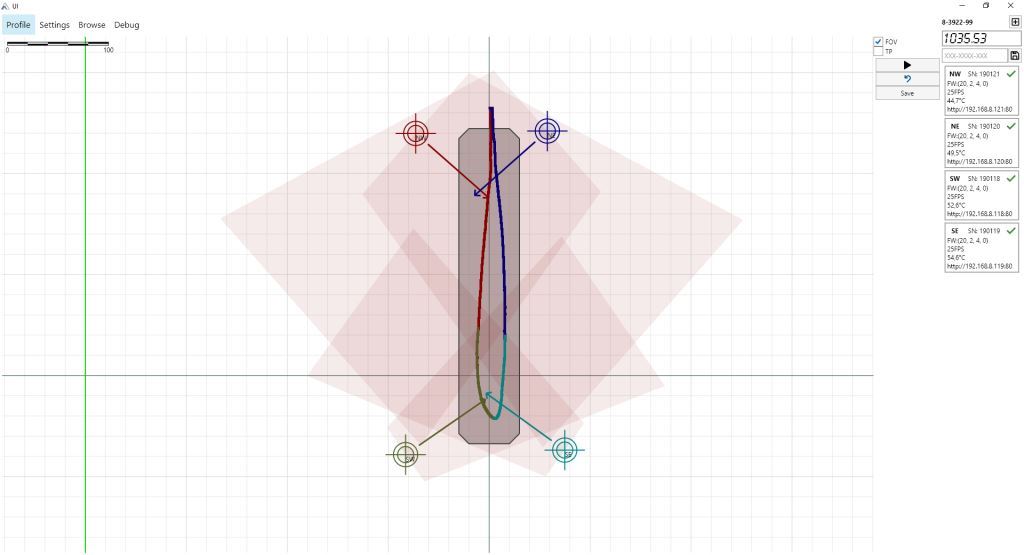

The process of blade geometric parameters measuring is a progressive laser scanning of the blade. The blade is chucked in manipulator and rotated vertically to minimize its deflection. The frame with measuring sensors moves along the guides on the surface plate. The frame movement is controlled by operator using an automated frame movement mechanism. The results of laser sensors scanning are processed by special software (software) «ASSISTER», installed on control panel computer. Based on the inspection results, a protocol of inspection results is generated automatically. Based on inspection protocol the decision on inspected product quality is made by specialist.

The main advantages of the «Geometra»system are:

› Measurement of geometric parameters of the blade in a non-contact way;

› Ability to control products with complex geometry;

› Increased accuracy of measuring linear values of deviation of parameters;

› Ability to measure angular values of deviation of parameters;

› Elimination of the influence of the human factor on the result of control;

› Increased measurement speed;

› In addition to measuring geometric parameters, the system allows you to obtain a 3D model of the controlled object;

› Control results are saved electronic writing automatically and results can be integrated into the enterprise database;

› Development, design, manufacture and commissioning automated non-destructive testing system,«on a turnkey basis», with a set of documentation enclosed and qualify of the Customer's specialists;

› An individual approach guarantees a comprehensive solution to the Customer's tasks for the control of specific products.